Coating Machine VFD Application Solutions

2022-09-01 | Application Case

Application Introduction

The Coating Machine is suitable for the production of PVC, Decorative Paint Paper and Solid Wood Veneer on the surface of various boards such as Wood, Aluminum-Plastic Profiles, and Foam Materials. Instead of the traditional paint process, it is used for the surface mount production such as Door Cover Line, Skirting Line, Gussets, Curtain Rods, Window Sills, Aluminum Alloy Doors & Windows, and Photo Frames. Using various forming pressure rollers to simulate the action of manual veneer, attach the surface decoration material to the surface of the base material. Generally, the center line or the highest point or the lowest point of the profile is selected as the starting point, and fix the position of the pressure roller along the profile surface contour point by point and in sequence to form the envelope of the profile.

This type of Coating Machine is a hot glue Coating Machine, uses solid glue,which is used after heating and melting in the hot glue box of the Coating Machine. Generally, the heating temperature of the coating glue is about 220 °C. Suit for sticking to Solid Wood Veneer and Decorative Paint Paper.

Equipment Structure and Operation Principle

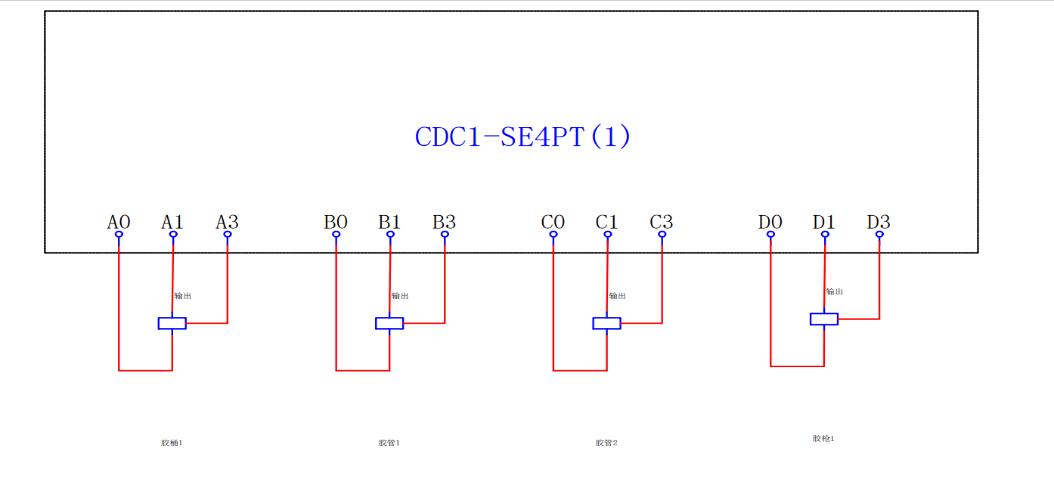

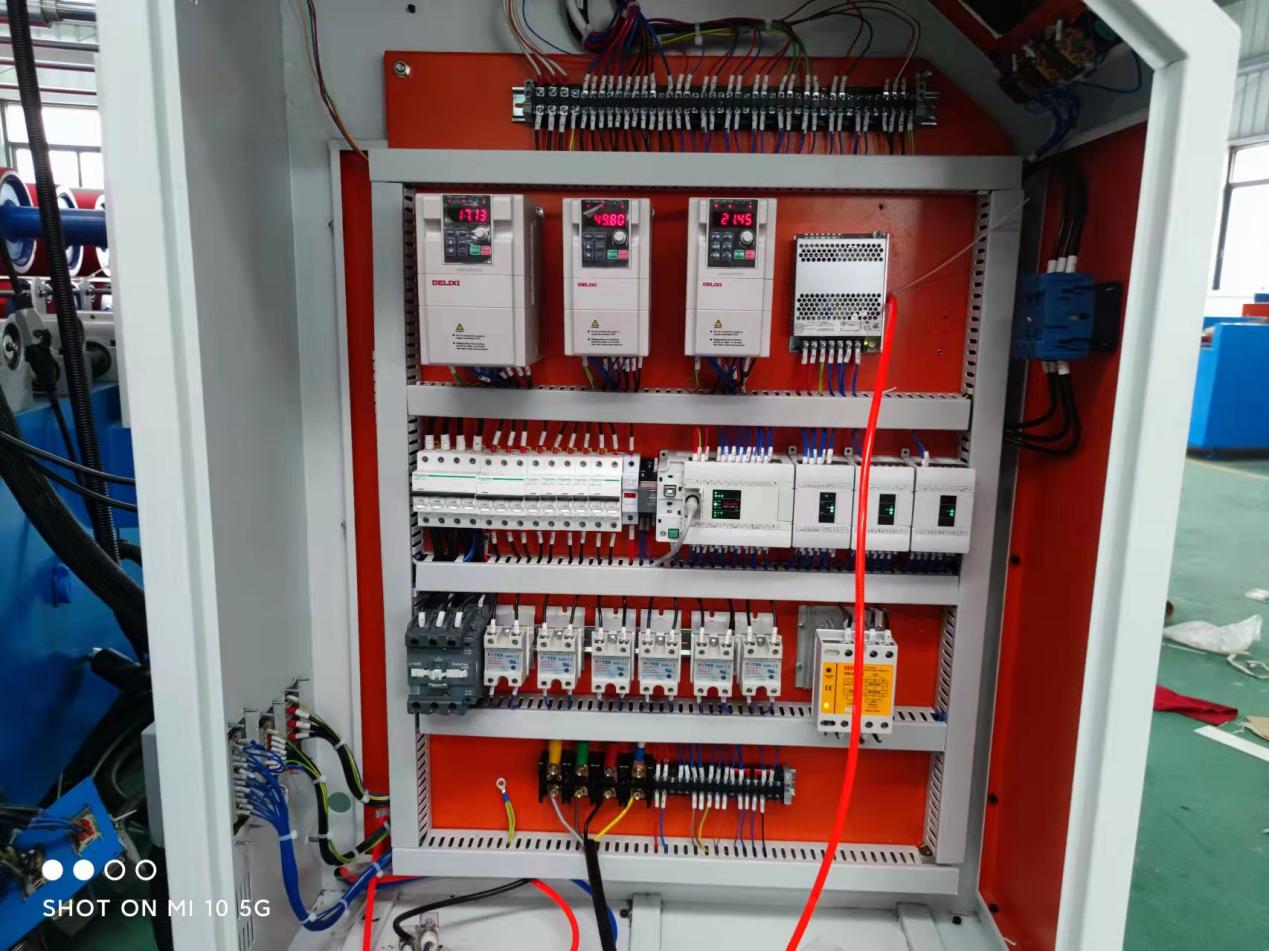

The equipment is mainly composed of three parts, melting glue, gluing, conveying, which corresponds to three Frequency Inverters. The conveying part adopts a 1.5KW Inverter to drive two 0.75KW Motors. The temperature acquisition uses 7 PCS PT100 thermal resistances, the control and display part adopts Delixi CDC1-S32T-A economical PLC and CDH-B070E HMI. The expansion selects a 16-point relay output module CDC1-SE16DR and two CDC1-SE4PT multi-function temperature acquisition modules.

|

Name |

Model |

Qty |

Description |

|

PLC |

CDC1-S32T-A |

1 |

Logic processing of the running process. |

|

HMI |

CDH-B070E |

1 |

Users can set parameters and monitor status data through the touch screen. |

|

Output Module |

CDC1-SE16DR |

1 |

Output point expansion for hosts with insufficient output points |

|

Temperature Acquisition Modules |

CDC1-SE4PT |

2 |

Perform temperature measurement, support a variety of temperature measurement sensors |

|

Frequency Inverter |

EM61 |

3 |

Control the three-part motor of conveying, melting glue and gluing. |

Operation Principle

The operation principle of the equipment is relatively simple. The main process requirements are that the linear speed of the conveyor belt and the rubber coating roller should be consistent, and the temperature change should not exceed ±0.5°C. For the former, the frequency can be calculated from the inherent mechanical parameters (wheel diameter, reduction ratio) through PLC and the HMI given speed, then written to the Inverter through real-time communication; the latter controls the heater through the PID command of the PLC, and the temperature control accuracy can reach ±0.1°C.

When starting up, the Frequency Inverter of the melting glue is limited by the temperature. If any one of the seven temperatures collected is less than the minimum temperature, the Frequency Inverter of the melting glue cannot be started.

Parameter wiring and debugging

Parameter debugging

For EM61 series inverter, the factory parameters can be suitable for most applications, so only five groups of parameters need to be set in this application.

|

Function code |

Function name |

Factory set value |

Description |

|

P0003 |

control method |

1 |

Select terminal control |

|

P0004 |

Method of Frequency Setting

|

0 |

Keyboard reference (communication input) |

|

P0011 |

acceleration time |

5.0 |

Control the acceleration and deceleration time of the motor |

|

P0012 |

deceleration time |

5.0 |

Control the acceleration and deceleration time of the motor |

|

P4.1.02 |

Slave station address |

According to the function |

Melting frequency is 1 Gluing frequency is 2 Transmission frequency is 3 |

For temperature control, If the application situation changes greatly, the factory PID parameters are not applicable and need to be self-tuning again.

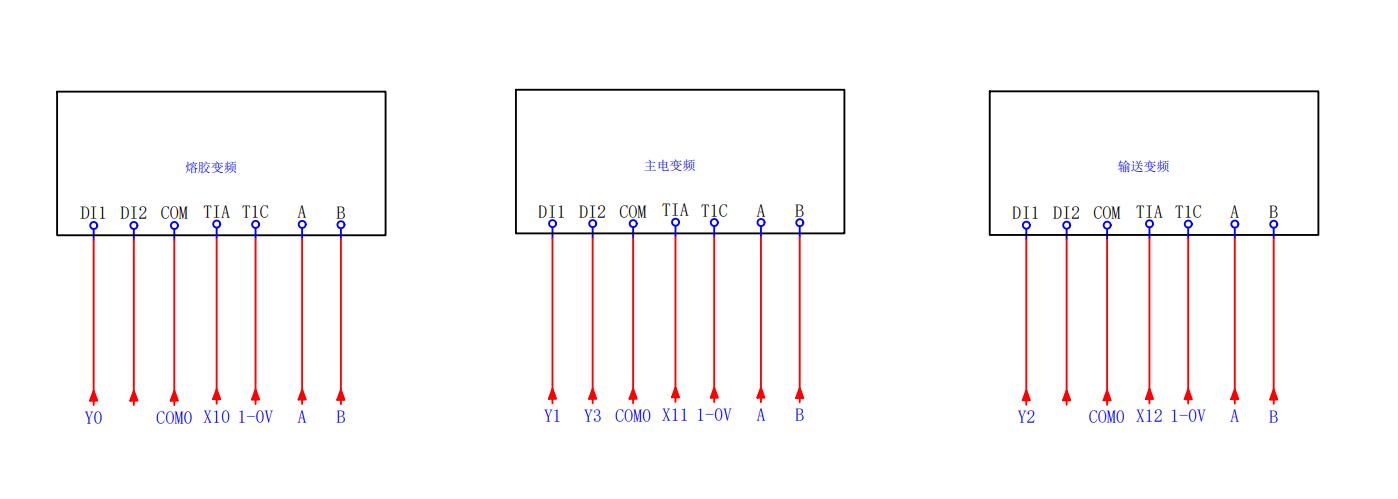

Device Wiring

Solution advantage

The EM60 series cost-effective inverter is matched with DELIXI economical PLC and HMI to reduce costs for users and increase product competitiveness.

The PID self-tuning algorithm of PLC is mature and stable, and one-key self-tuning can get all the gain parameters of the PID, which greatly saves the debugging time.

A large amount of upgrade space is reserved for users to upgrade and transform in the future.

As a top 5 boiler manufacturers in China, Linkjoint has plenty of accolades from our valued customers due to its sophisticated design, excellent quality, eco-friendly thermal solutions, state-of-the-art equipment and sustaining innovation. Some of latest information about our products and exhibitions we attended are shown as follows.

Canton Fair Gain Customer Trust And Recognition

Dexi participated in the Canton Fair from April 15 to April 19, and the first phase of the 133rd Canton Fair, which lasted for five days, ended successfully! After three years of epidemic, Canton Fair fully resumed offline exhibition, attracting buyers from 229 countries and regions around the world, an unprecedented event.

Sales Engineer Recruitment

Delixi Electric is expanding its team and looking for passionate Technical Sales Engineers in India, Vietnam, and Turkey to drive the sales of our innovative Variable Frequency Drives (VFDs) and cutting-edge industrial control products.

Application of VFD in air compressor

How is VFD applied to water pumps? This article introduces why to use VFD control pump? What are the advantages of using Delisi VFD? Finally, the solution of vfd in practical application is given. This section describes other application scenarios.

Get Best Service And Discounts

Please give us a message for your enquiry . order or advice. Thanks a lot.

Send Message